Forged by a centuries-old history, the wine industry is at an inflection point where it must adapt to keep up with changing consumer tastes as well technology advancements of their tools without losing quality. Leading the way in industry innovation, wine bottling solutions have been designed to ensure that both speed and sterility requirements are met while maintaining wines fragile buquet properties.

Technological innovations in Bottling

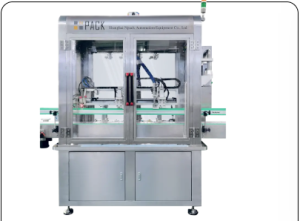

Today wine bottling lines can accommodate a range of mods and provide precision with advanced technologies. E.g. nowadays one can buy filling machines suitable for between 1,000 to fifteen thousand bottles an hour -- the exact numbers depend on facility size and automation leveluts Made to reduce the oxygen exposure of a wine, which is essential for allowing it stand straight and truly show off its potential flavor profile.

Modern-day vacuum filling technologies are integrated with automatic bottle filling systems that significantly improved the tedious process. It speeds up the bottling process, which as an added bonus helps clear wine to have lower dissolved oxygen in beverage storage. These are now able to deliver sharply reduced oxygen levels of 0.1 mg per liter at the bottling point, something Trepuzzi said played an important role in selecting them over more conventional solutions.

Proper Hygiene and Sterilization Practices

In wine bottling there are no two ways about it, very high hygiene standards have to be followed. Modern bottling facilities have sterilization stations, either with steam or chemicals to ensure that each bottle is free from contaminants before filling. The solution integrates CIP (Clean-In-Place) being cleaned in-depth elements without the equipment disassembling, saving time and manpower.

In addition, the change to sustainable sterilization procedures such as ozone-based systems highlights an important value of sustainability in the industry. And with those systems, which totally eradicate every kind of germs but leave no trace of toxic stuff once they have completed to kill even the most little bad thingies aligning them-selfs to gentler global manufacturing practices.

Customize (for adaptation)

Such flexibility is particularly important for wineries that make many different types of products as it allows the bottling line to be adapted and customised in order to accommodate multiple bottle shapes and sizes. Most modern bottling machines are equipped with adjustable parts that can easily convert back and forth, often from small artisanal bottle formats to large commercial sizes.

It should be normalized into Quality Control

The bottling process seamlessly includes quality control. The cameras and sensors in place also keep careful track of whether each bottle is filled to the limit, as well as has its cap placed correctly with exact precision This information is made available in real time, so that any deviations can quickly be identified and rectified, maximising efficiency; wastage is minimised ensuring only the highest quality product reaches consumers.

Benefits Of Innovative Wine Bottling Solutions

By investing in truly innovative bottling solutions wineries can give themselves a competitive edge against their counterparts. Improves production productivity and also features an improved item top quality & market durability The new bottle technology also provides an extra measure of speed and versatility, with environmental and safety benefits that the industry demands.

As the wine industry transitions, wineries that hope not to "disappear" in an increasingly crowded and competitive market will have no choice but to also transition into a world where keeping abreast of state-of-the-art bottling technologies is central to their long-term survival. By embracing these new standards we ensure all the tradition in winemaking is paired with modern manufacturing delivering our best product to wine lovers worldwide.